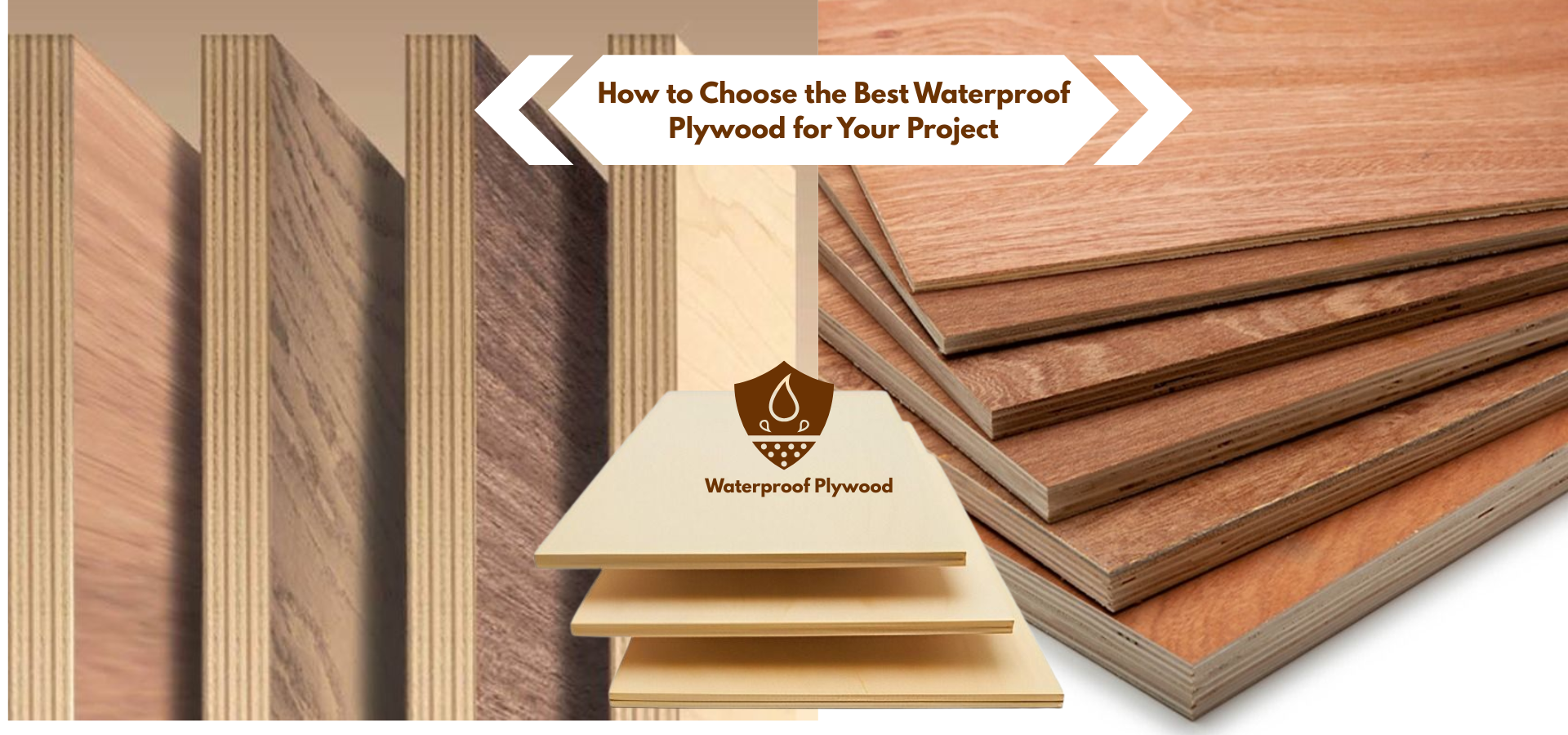

How to Choose the Best Waterproof Plywood for Your Project

- January 23, 2026

Choosing materials for a home or commercial project isn’t just about looks—it’s about how those materials perform years down the line. Imagine installing beautiful kitchen cabinets, only to see them swell and warp within a monsoon season. This is exactly why Waterproof Plywood plays such a critical role in modern construction and interior design.

Whether you’re planning a residential renovation, a commercial fit-out, or outdoor furniture, this guide will help you understand what Waterproof Plywood is, why it matters, and how to choose the best option for your project—with practical tips you can actually use.

What Is Waterproof Plywood?

Waterproof Plywood is engineered to perform in moisture-prone environments where ordinary plywood often fails. Unlike standard panels, these sheets are bonded with phenolic resin, a high-performance synthetic adhesive that resists water penetration and prevents internal damage.

Picture a bathroom vanity or a kitchen cabinet near a sink. Regular plywood absorbs moisture, leading to swelling and delamination. Waterproof Plywood, on the other hand, stays dimensionally stable—even with frequent exposure to humidity and water splashes.

Key structural advantage:

Waterproof Plywood uses a cross-laminated construction, where each layer is placed perpendicular to the next. This design significantly reduces expansion, contraction, and warping caused by temperature and moisture fluctuations.

Pro Tip:

If your project involves kitchens, bathrooms, basements, or coastal areas, always prioritize phenolic resin–bonded plywood over standard interior-grade sheets.

Why Waterproof Plywood Is Worth the Investment

Selecting Waterproof Plywood isn’t just about avoiding damage—it’s about long-term performance and peace of mind.

1. High Resistance to Water

Thanks to phenolic resin bonding, Waterproof Plywood resists water absorption far better than conventional plywood. This makes it ideal for high-humidity zones and wet conditions.

Pro Tip:

Ask suppliers whether the plywood meets boiling water resistance (BWR) or boiling water proof (BWP) standards for added assurance.

2. Long-Term Durability

Moisture is one of the biggest enemies of wood. Waterproof Plywood combats this by preventing layer separation and surface degradation, ensuring a longer lifespan even in demanding environments.

Real-world scenario:

In commercial kitchens or cafés, frequent cleaning and steam exposure can destroy regular plywood. Waterproof Plywood maintains strength and finish despite daily wear.

Pro Tip:

For high-traffic or commercial spaces, durability often outweighs initial cost savings.

3. Superior Structural Stability

The cross-laminated structure distributes stress evenly across the panel, reducing cracks and surface distortion.

Pro Tip:

For large panels like wardrobes or wall cladding, cross-laminated Waterproof Plywood ensures a smoother, more stable finish over time.

4. Suitable for Heavy-Duty Applications

From construction flooring to outdoor furniture, Waterproof Plywood can handle significant loads without compromising structural integrity.

Pro Tip:

If the plywood will support weight—such as flooring or countertops—opt for higher thickness and density.

5. Exceptional Versatility

Waterproof Plywood adapts to multiple applications:

- Furniture and cabinetry

- Wall paneling

- Flooring substrates

- Outdoor and marine use

Pro Tip:

Choose the grade of Waterproof Plywood based on usage—interior wet areas and exterior environments require different performance levels.

How to Choose the Best Waterproof Plywood for Your Project

Understanding features is one thing—choosing the right product is another. Here’s how to make a confident decision.

1. Check the Resin Bonding Quality

The effectiveness of Waterproof Plywood largely depends on the quality of the phenolic resin used. High-grade resin ensures better water resistance and longer life.

Pro Tip:

Low-quality resin may look fine initially but fails under prolonged moisture exposure.

2. Select the Right Thickness and Density

Thicker sheets offer better load-bearing capacity and improved moisture resistance.

General guidance:

- Furniture & cabinets: Medium thickness

- Flooring & structural use: Higher thickness

Pro Tip:

Never compromise thickness for price if the application demands strength.

3. Ensure Cross-Laminated Construction

Cross-lamination minimizes the effects of humidity and temperature changes, making the plywood more dimensionally stable.

Pro Tip:

This feature is especially important in regions with extreme seasonal variations.

4. Look for Certifications and Standards

Quality certifications ensure the plywood has been tested for strength, bonding, and water resistance.

Pro Tip:

Certified Waterproof Plywood offers predictable performance and better return on investment.

5. Consider Manufacturer Credibility

A reputable manufacturer is more likely to maintain consistent quality, use premium raw materials, and follow strict production standards.

Pro Tip:

Brand reliability often translates into fewer issues during installation and usage.

Common Applications of Waterproof Plywood

Because of its moisture resistance and strength, Waterproof Plywood is widely used across industries.

Construction Flooring

Provides a stable base that resists moisture-related damage in kitchens, bathrooms, and basements.

Marine and Coastal Use

Performs reliably in boat interiors and structures exposed to constant humidity.

Outdoor Furniture

Ideal for garden furniture, decking, and exterior fixtures where weather resistance is essential.

Wall Paneling and Cabinets

Ensures long-lasting performance in moisture-prone indoor spaces without warping or swelling.

Pro Tip:

Matching the plywood grade to the application ensures maximum performance and durability.

Final Takeaway: Build Smarter with Waterproof Plywood

Waterproof Plywood is more than just a construction material—it’s a long-term safeguard against moisture damage, structural failure, and costly repairs. By understanding resin quality, thickness, structure, and application requirements, you can confidently choose the best Waterproof Plywood for your project.

The real value lies in durability, stability, and peace of mind. When chosen correctly, Waterproof Plywood enhances not just the lifespan of your project—but also its overall performance and finish.

If your goal is to build spaces that last through seasons, usage, and time, Waterproof Plywood is not an option—it’s a necessity.